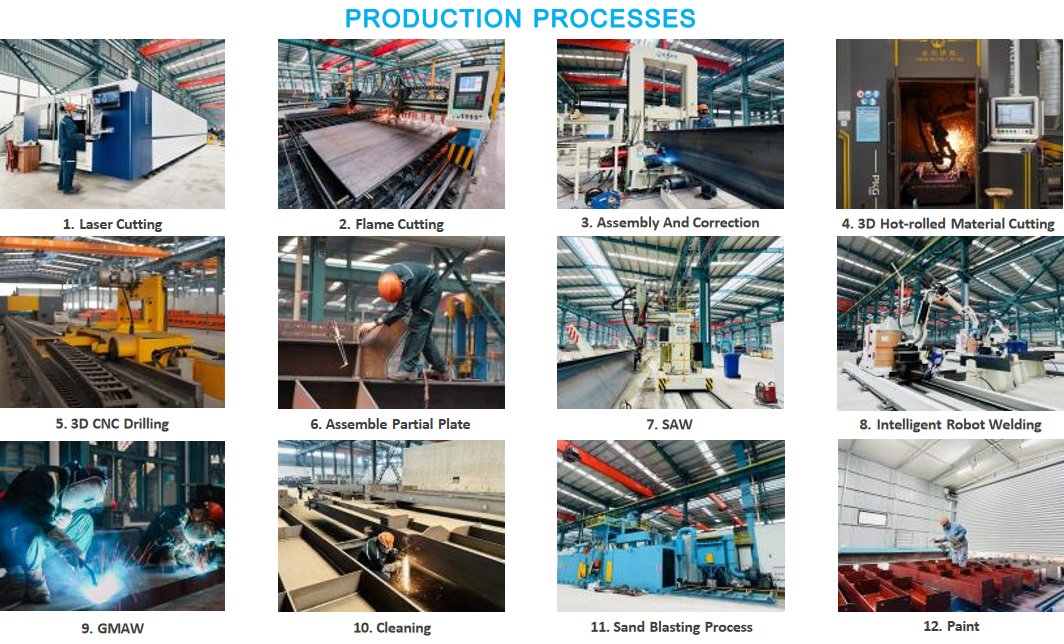

SANGO Steel Structure Production Process

1. Laser Cutting

High-precision cutting of steel materials is performed using laser cutting equipment to obtain workpieces that meet design dimensions. The process produces smooth cuts with a small heat-affected zone, making it ideal for sheet metal processing requiring high accuracy.

2. Flame Cutting

Steel is melted and removed using high-temperature flames to achieve efficient cutting of thick plates. This is a cost-effective traditional cutting method, suitable for thick plate processing with relatively relaxed precision requirements.

3. Assembly And Correction

All components are assembled as a whole, fixed with specialized fixtures, and precision correction is carried out on the assembled structure to eliminate assembly deformation and ensure the overall flatness and verticality of the structure.

4. 3D Hot-rolled Material Cutting

Precision cutting is performed on 3D structural components such as hot-rolled profiles, adapting to complex profile cross-sections and spatial angle requirements to provide accurate components for subsequent assembly.

5. 3D CNC Drilling

High-precision 3D hole processing is completed on workpieces using 3D CNC drilling equipment, ensuring that the position accuracy and perpendicularity of holes meet assembly requirements.

6. Assemble Partial Plate

Cut and drilled partial plates are pre-assembled according to design drawings, with the relative positions of each plate positioned and fixed to lay the foundation for overall structural assembly.

7. SAW (Submerged Arc Welding)

The main welds of components are welded using the submerged arc welding process, which offers high welding efficiency and stable weld quality, suitable for batch welding of long welds and thick plates.

8. Intelligent Robot Welding

Automated welding is achieved via industrial robots, improving welding efficiency and consistency. It is particularly suitable for complex welds and multi-station repetitive welding scenarios, ensuring stable weld quality.

9. GMAW (Gas Metal Arc Welding)

Welding is performed using gas metal arc welding, featuring visible arcs and flexible operation. It is suitable for welding medium and thin plates, as well as for weld repair and finishing to enhance weld appearance quality.

10. Cleaning

After welding, components are cleaned to remove slag, spatter, and oil stains from the weld surface, providing a clean workpiece surface for subsequent surface treatment processes.

11. Sand Blasting Process

The surface of components is blasted with high-speed abrasive to remove rust and oxide scales, achieving a uniform rough surface to improve the adhesion of the subsequent anti-corrosion coating.

12. Paint

Anti-corrosion and decorative coatings are applied to the sand-blasted components, including primers and topcoats, to enhance the rust resistance, corrosion resistance, and weather resistance of the steel structure, while also improving its aesthetic appearance.